Quality control

OU Quality control is an organizational unit within the PPT-TMO S.A. performing the following activities:

Implementation of the Integrated Quality Management System (QMS) ISO 9001: 2008 and the Environmental Management System (EMS) ISO 14001:2004, which are introduced to the PPT-TMO S.A. in 2013 and recertified in 2014 by the renowned certification company TÜV, Germany. All activities related to certification and recertification are within the competence of the Executive Director of PPT-TMO S.A. and a quality management representative, who is also the Administrator of the OU Quality Control. Cooperation with the management of PPT-TMO S.A. results in the fulfillment of the requirements of ISO 9001: 2008 and ISO 14001: 2004, as well as the customer satisfaction, notes of which have been made.

Implementation of the Integrated Quality Management System (QMS) ISO 9001: 2008 and the Environmental Management System (EMS) ISO 14001:2004, which are introduced to the PPT-TMO S.A. in 2013 and recertified in 2014 by the renowned certification company TÜV, Germany. All activities related to certification and recertification are within the competence of the Executive Director of PPT-TMO S.A. and a quality management representative, who is also the Administrator of the OU Quality Control. Cooperation with the management of PPT-TMO S.A. results in the fulfillment of the requirements of ISO 9001: 2008 and ISO 14001: 2004, as well as the customer satisfaction, notes of which have been made.

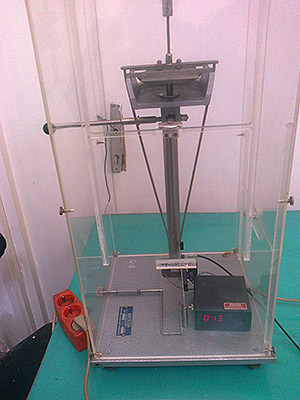

Quality control performs quantitative and qualitative control of parts, monitors technological processes in the course of providing services and reports on quality, in accordance with ISO 9001:2008 and ISO 14001:2004 standards. Measurements and tests are performed using the verified measuring equipment, by trained and qualified personnel. Within the Quality Control unit, there are metallographic and chemical laboratories that have the appropriate equipment and expert employees. Cooperation is carried out with internal and external customers. Customer Satisfaction has been noted.

Quality control performs quantitative and qualitative control of parts, monitors technological processes in the course of providing services and reports on quality, in accordance with ISO 9001:2008 and ISO 14001:2004 standards. Measurements and tests are performed using the verified measuring equipment, by trained and qualified personnel. Within the Quality Control unit, there are metallographic and chemical laboratories that have the appropriate equipment and expert employees. Cooperation is carried out with internal and external customers. Customer Satisfaction has been noted.

Fire safety and environmental protection are implemented in accordance with all applicable legislation and regulations, in compliance with ISO 14001: 2004. The results of checks and inspections, information on waste movement and delivery of the required records are forwarded to the competent ministries of the Government of the Republic of Serbia, as well as competent persons in local government. Staff training is done by training plans prepared in advance.

Fire safety and environmental protection are implemented in accordance with all applicable legislation and regulations, in compliance with ISO 14001: 2004. The results of checks and inspections, information on waste movement and delivery of the required records are forwarded to the competent ministries of the Government of the Republic of Serbia, as well as competent persons in local government. Staff training is done by training plans prepared in advance.

Safety at work and health protection are in compliance with applicable regulations and inspection supervision. Quality control unit is actively engaged in reviewing the work equipment, procurement and control of the use of means for personal protection, and creating plans for and implementation of initial and regular medical examinations, as well as continuous training of employees for safe and healthy work.

Safety at work and health protection are in compliance with applicable regulations and inspection supervision. Quality control unit is actively engaged in reviewing the work equipment, procurement and control of the use of means for personal protection, and creating plans for and implementation of initial and regular medical examinations, as well as continuous training of employees for safe and healthy work.

Metrology within the OU Quality Control is involved in planning, maintenance, procurement of new and checking of the existing measuring equipment and devices used in the process of controlling the quality of services provided in accordance with ISO 9001: 2008.

Metrology within the OU Quality Control is involved in planning, maintenance, procurement of new and checking of the existing measuring equipment and devices used in the process of controlling the quality of services provided in accordance with ISO 9001: 2008.

Quality Control monitors the processes of:

- Galvanic protection,

- Thermal treatment and

- Protective coloring and varnishing;

Quality control has laboratories for:

Chemical analysis of galvanic baths, processes of galvanic protection, thermal treatment and protective coloring and varnishing, which are equipped with modern appliances and devices.

Thickness, adhesion, corrosion resistance and porosity of coatings, as well as hardness and defects after heat treatment, are controlled.

Equipment and devices are regularly checked in accredited laboratories, from which we get the test results.

Reports and certificates of quality for all operations performed on are issued at client's request.

Gallery: Pictures of the equipment for measuring of the coating thickness, calibrated and tested micrometers and devices for measuring the hardness of coatings and the material after thermal treatment, as well as laboratories for chemical analysis are shown.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Srpski

Srpski